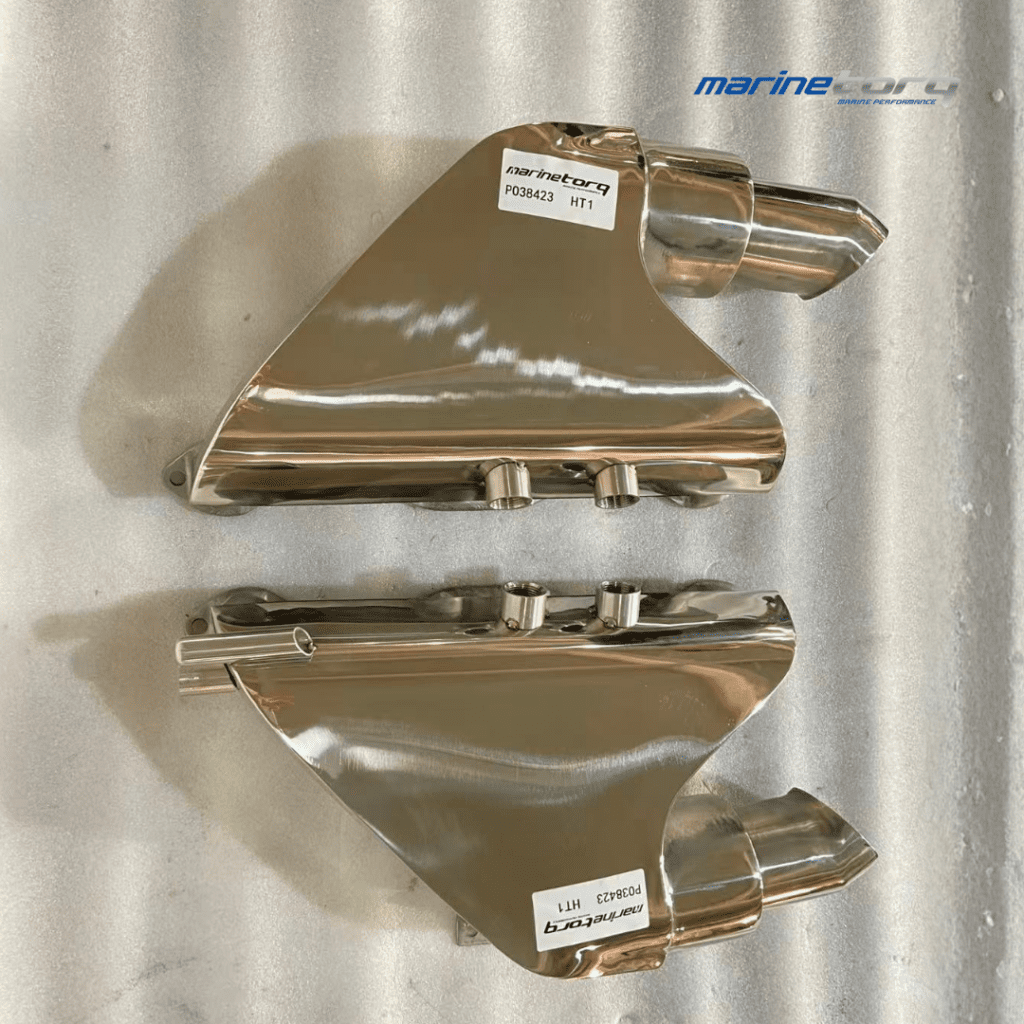

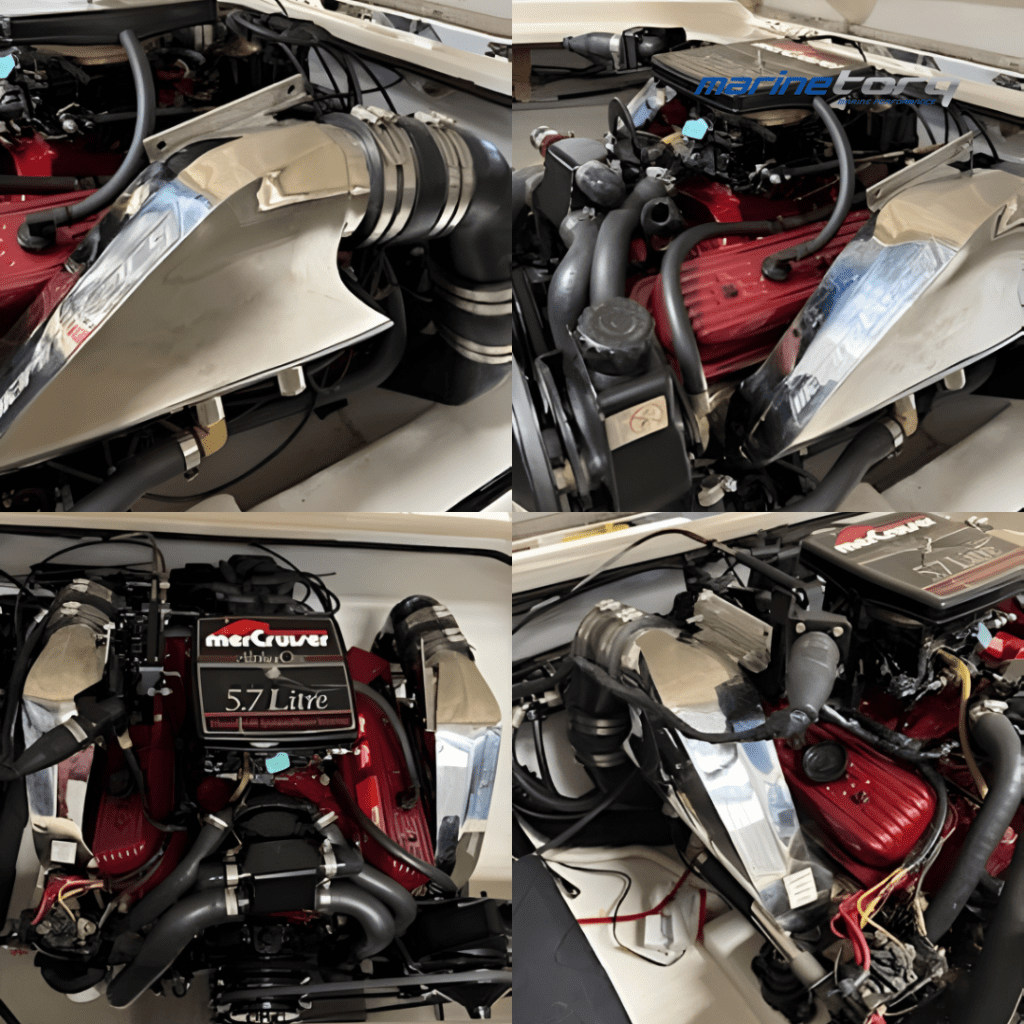

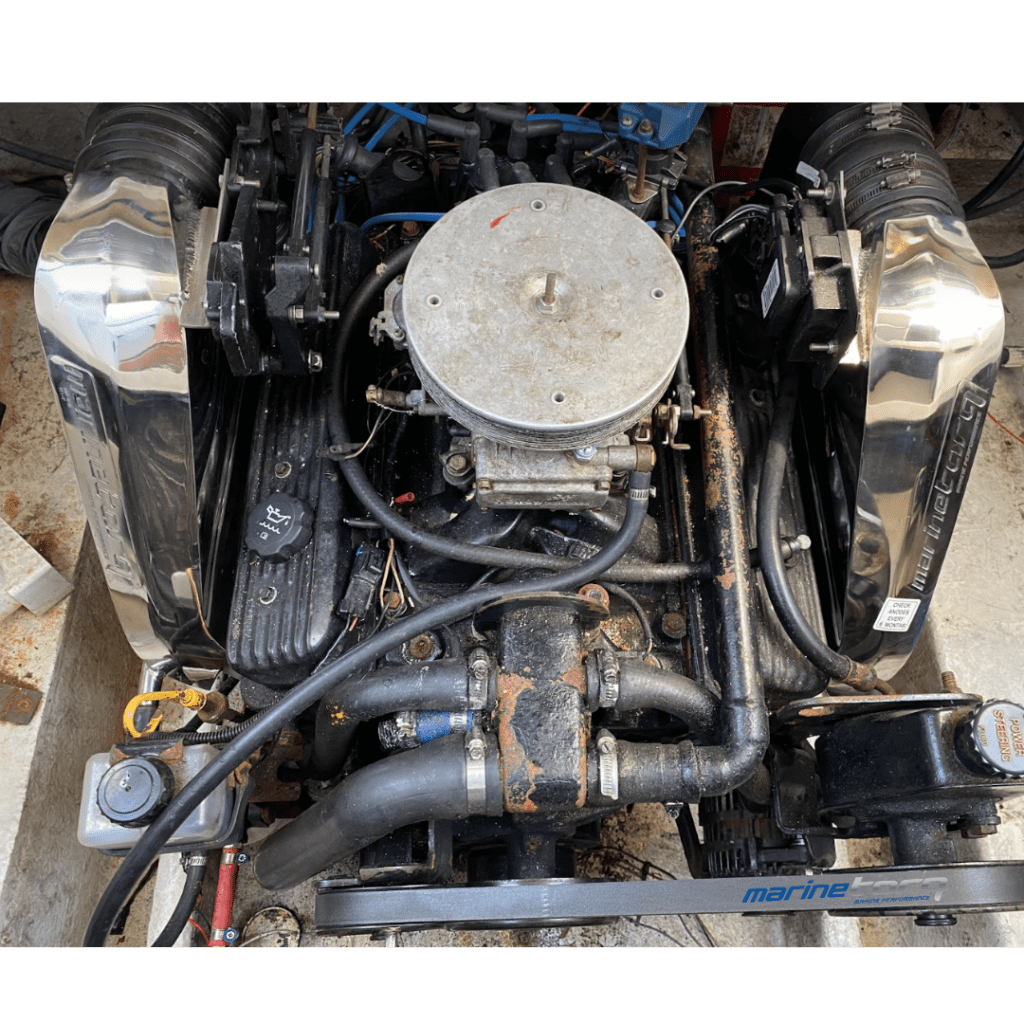

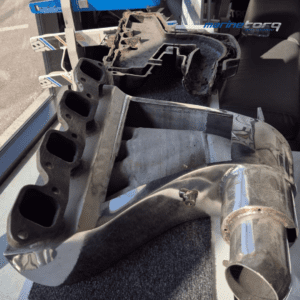

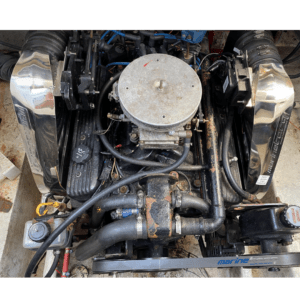

Mercruiser Wet-Joint 5.0L & 5.7L V8 Small Block Chev Exhaust Manifold Set: 1980 to 2003

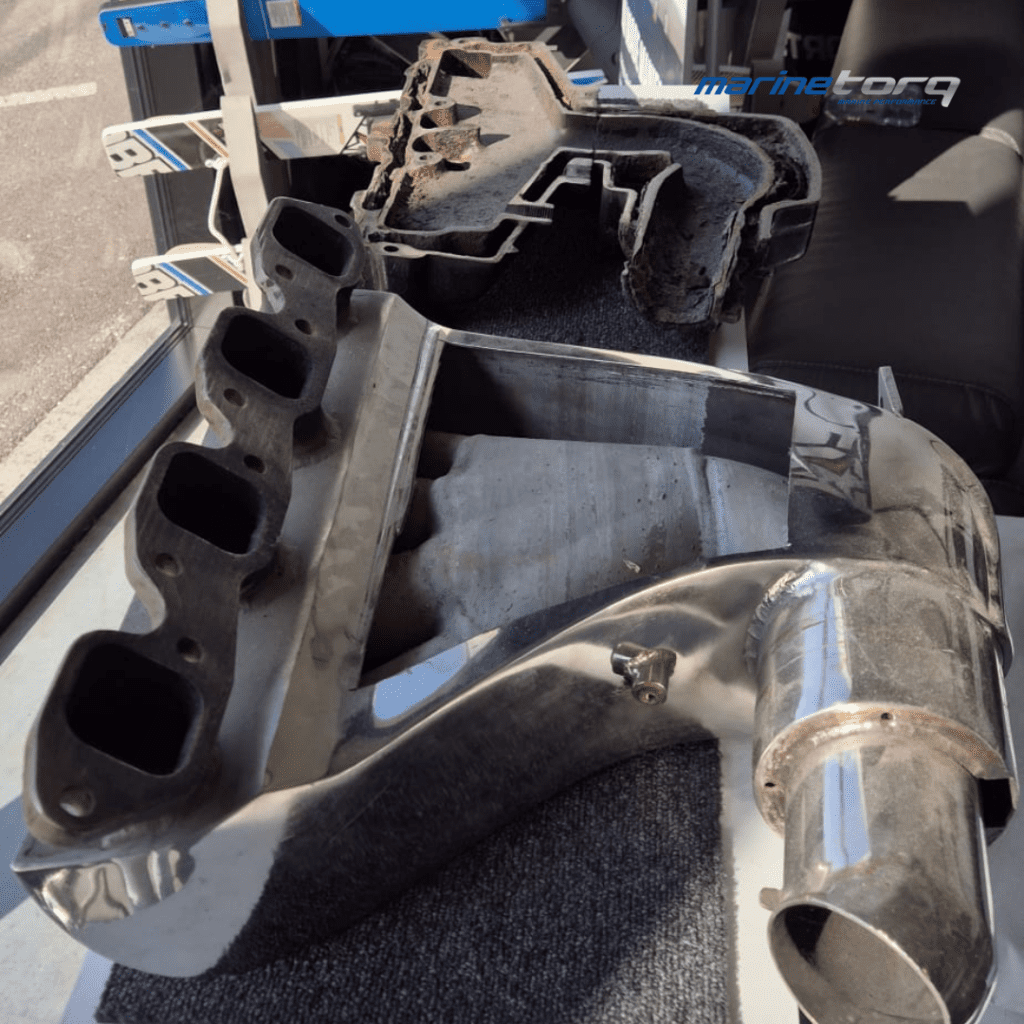

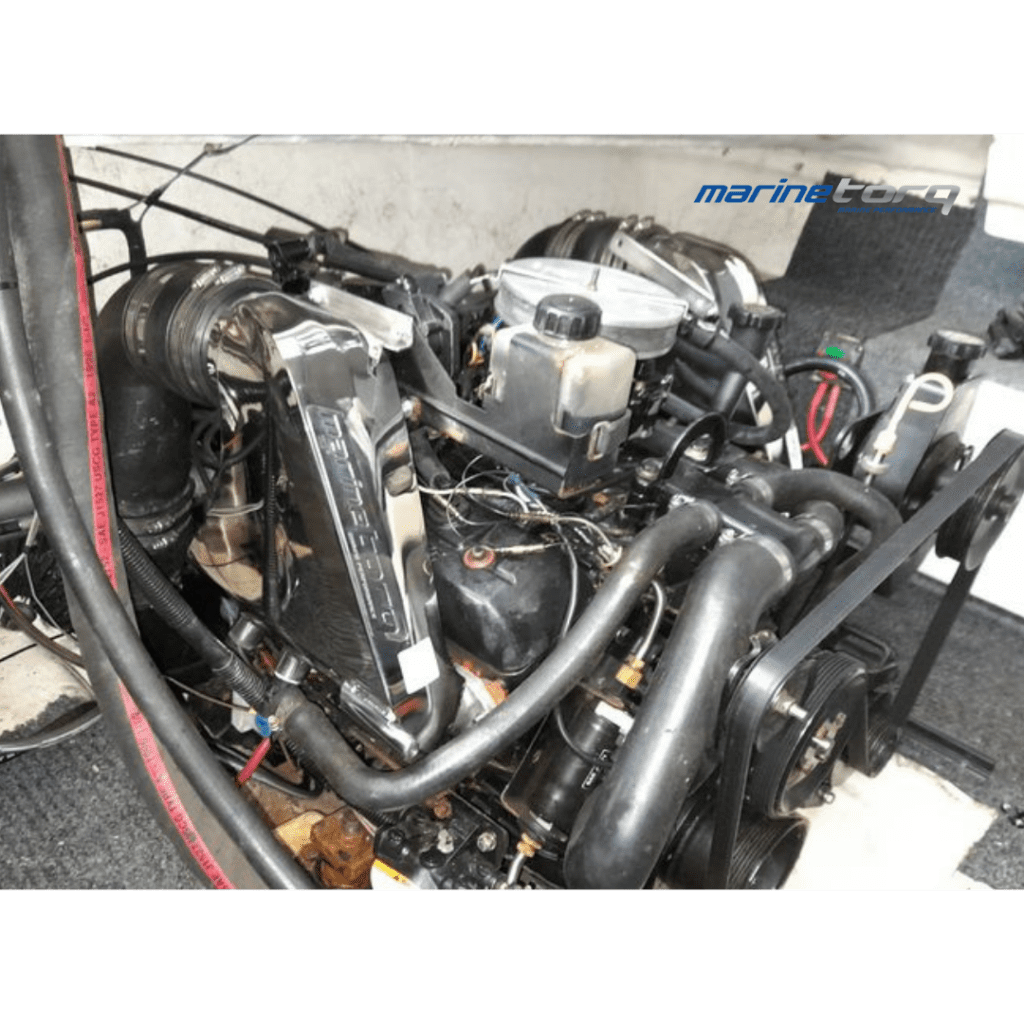

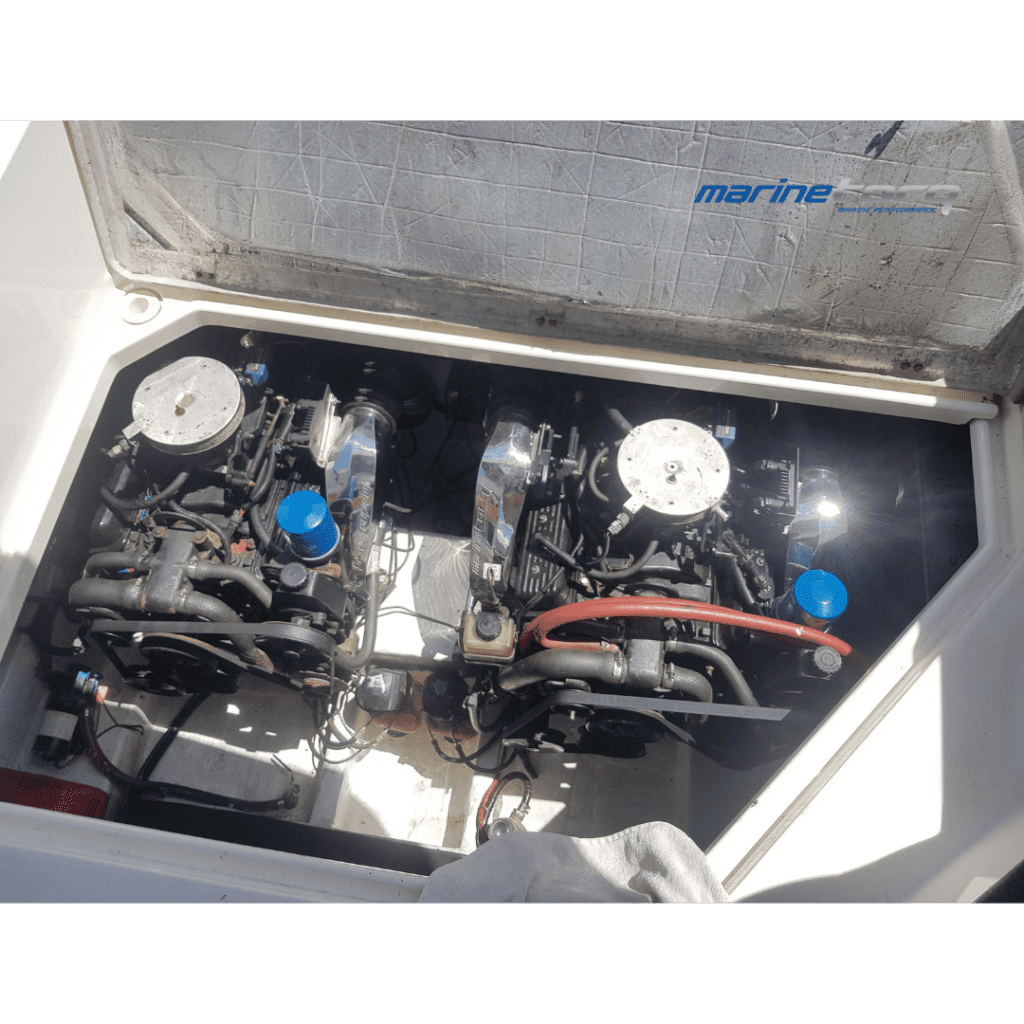

Have your cast iron manifolds corroded and failed, or does your boat feels sluggish and you’ve noticed an increase in fuel consumption? As a boat owner, no doubt you understand the challenge of keeping everything running smoothly, all without burning a hole in your wallet. If you are looking for security against leaking, corrosion and engine failure, plus less maintenance and a boost in performance- then stainless steel manifolds are the ideal solution for you.

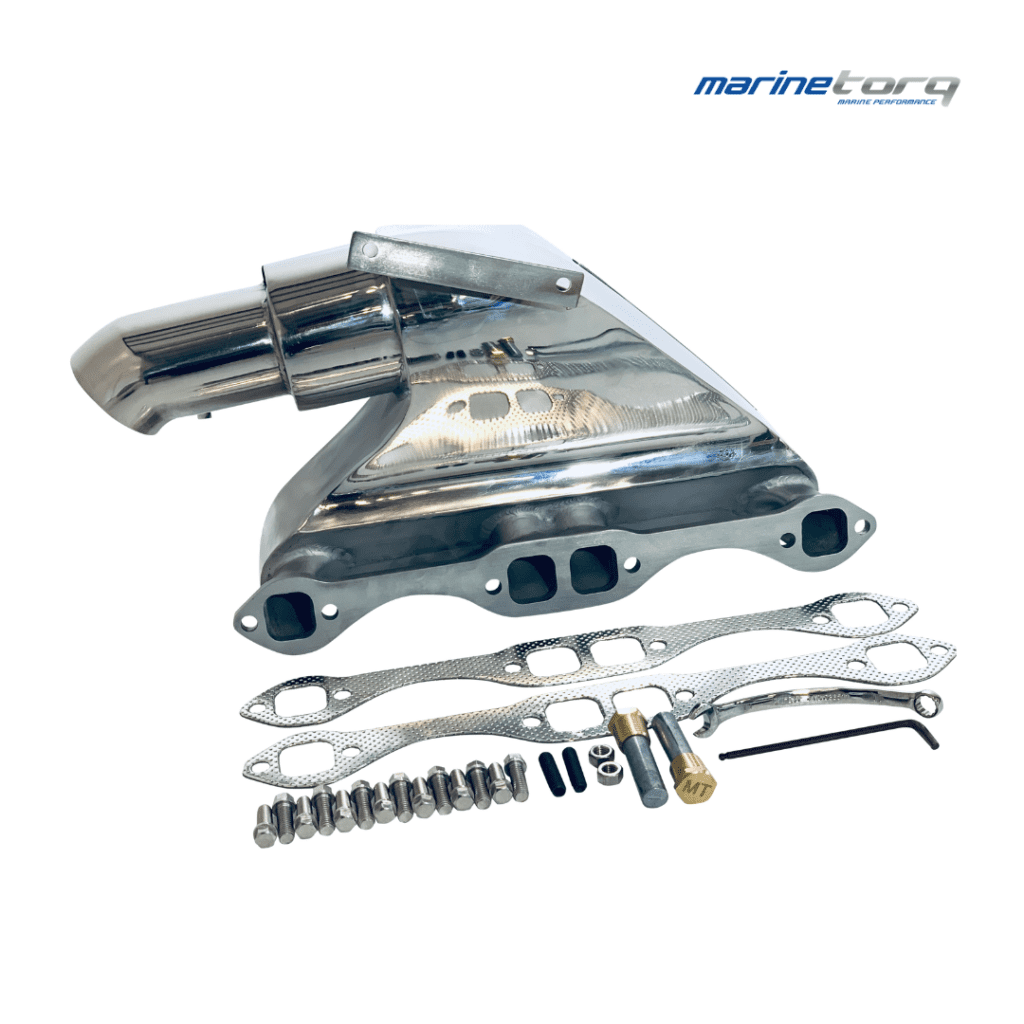

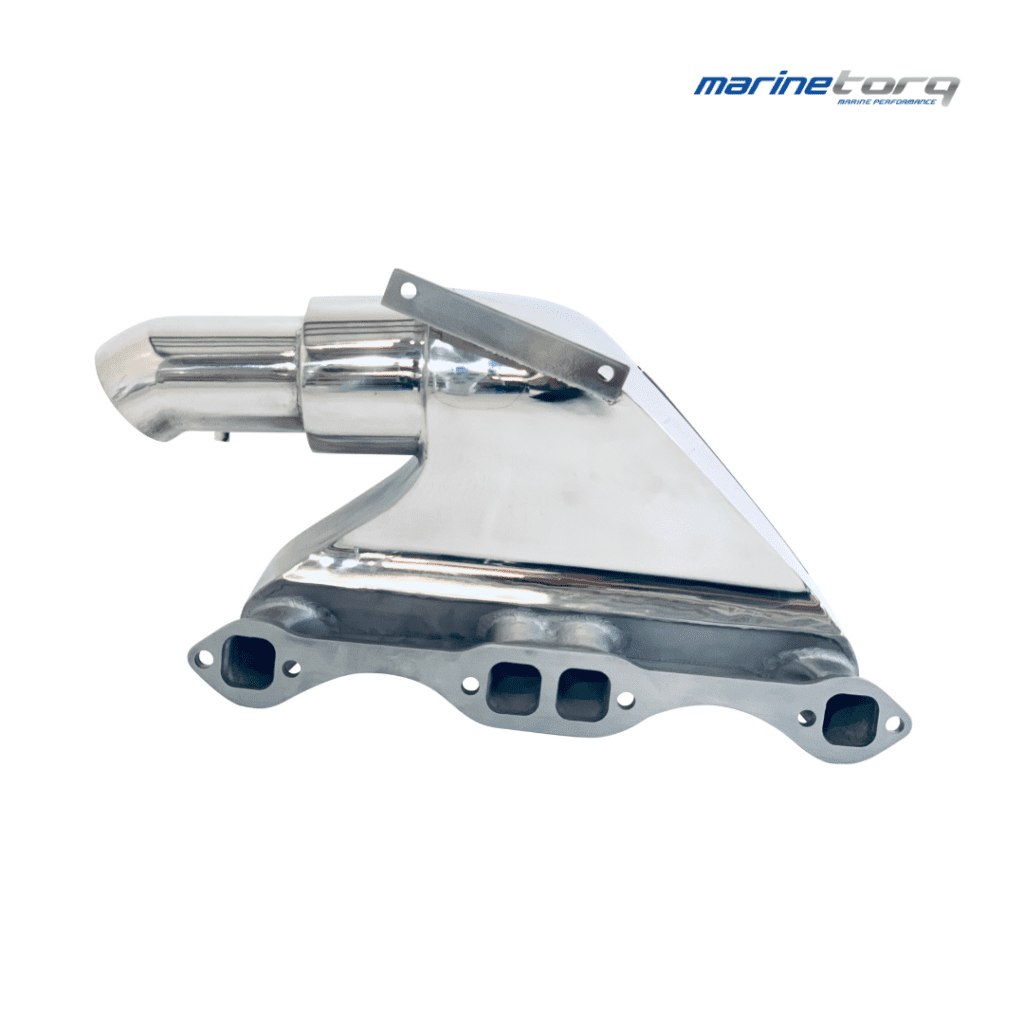

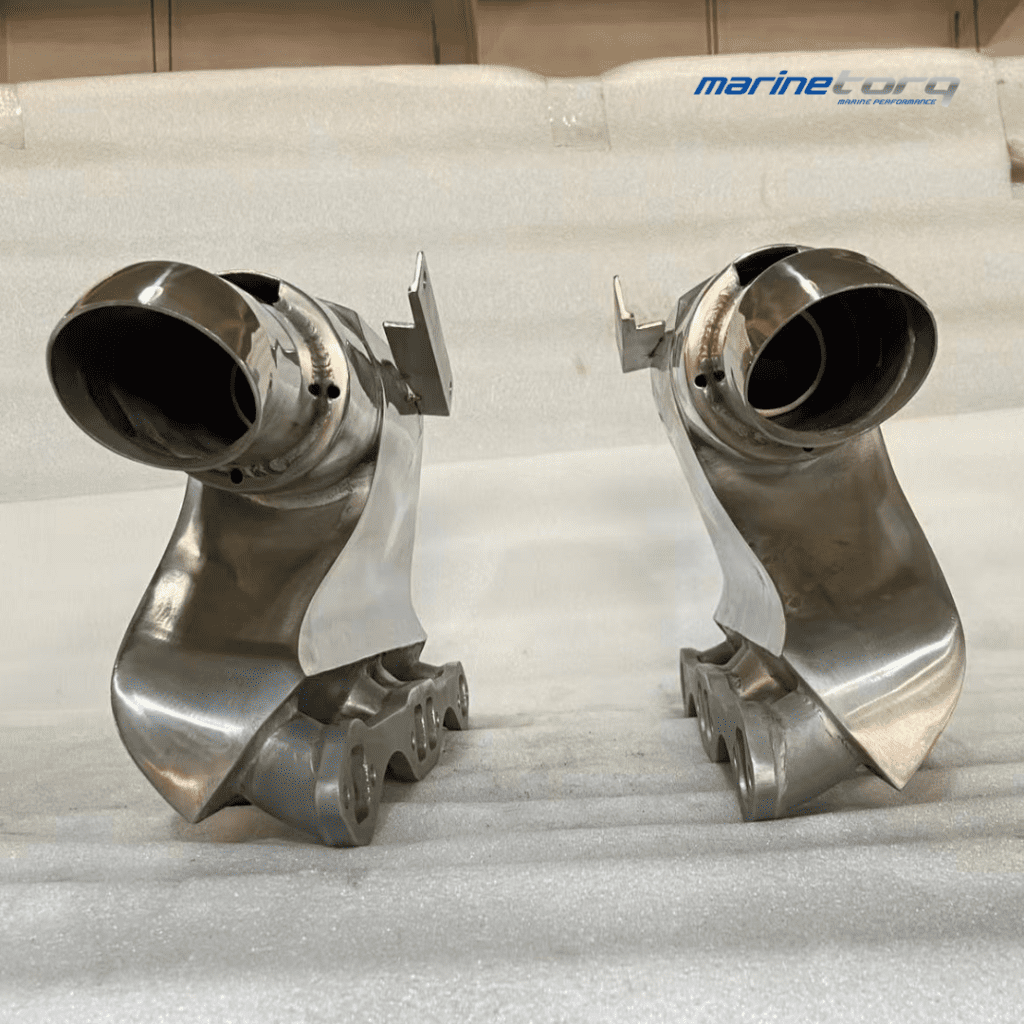

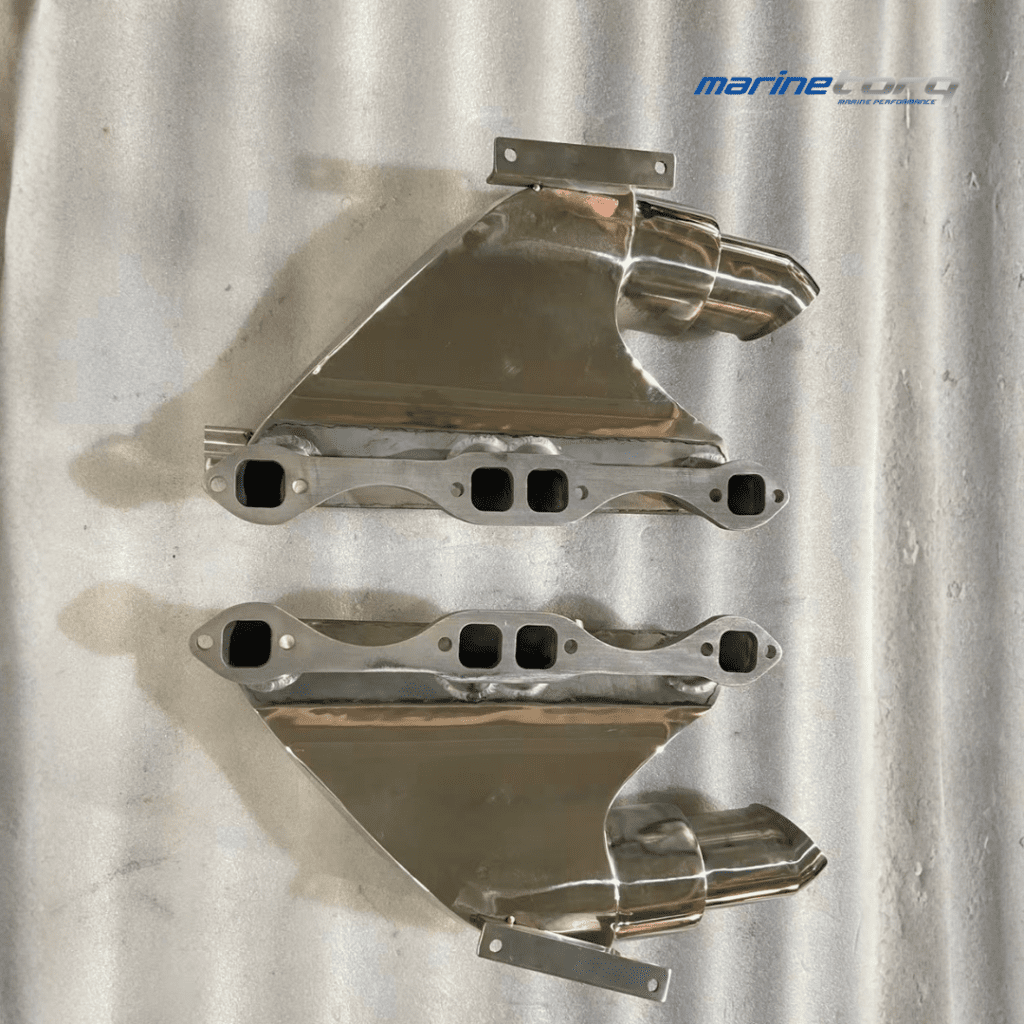

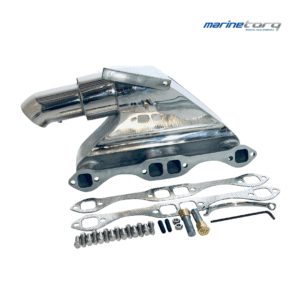

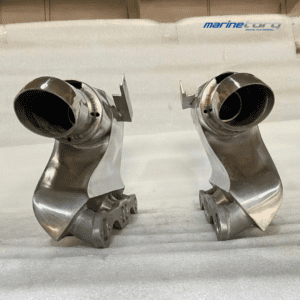

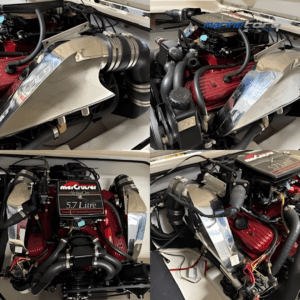

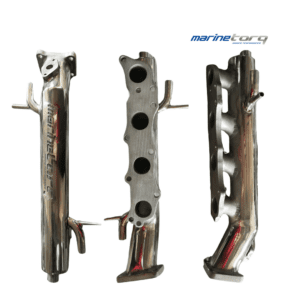

MarineTorq manifolds are suited to both petrol and diesel inboard engines and are backed by a 5-year warranty. Manufactured from premium stainless steel, the unique one-piece construction combines the spacers, risers and elbows all in one design. This completely eliminates the risk of leaking, rusting and gasket failure. A stainless steel water jacket provides an extra layer of protection and increases the cooling process for improved performance.

The steel used in both the manifold and the water jacket is 2mm thick, and undergoes extensive testing for cracking and leaking before leaving the factory. Stainless steel is an effective barrier against rust, plus runs cooler for improved engine efficiency and performance. If used as a cast iron replacement, stainless steel will also save you up to 80% in dead weight at the stern, providing a noticeable difference in power and fuel economy. Read more on the benefits of stainless steel vs cast iron manifolds here.

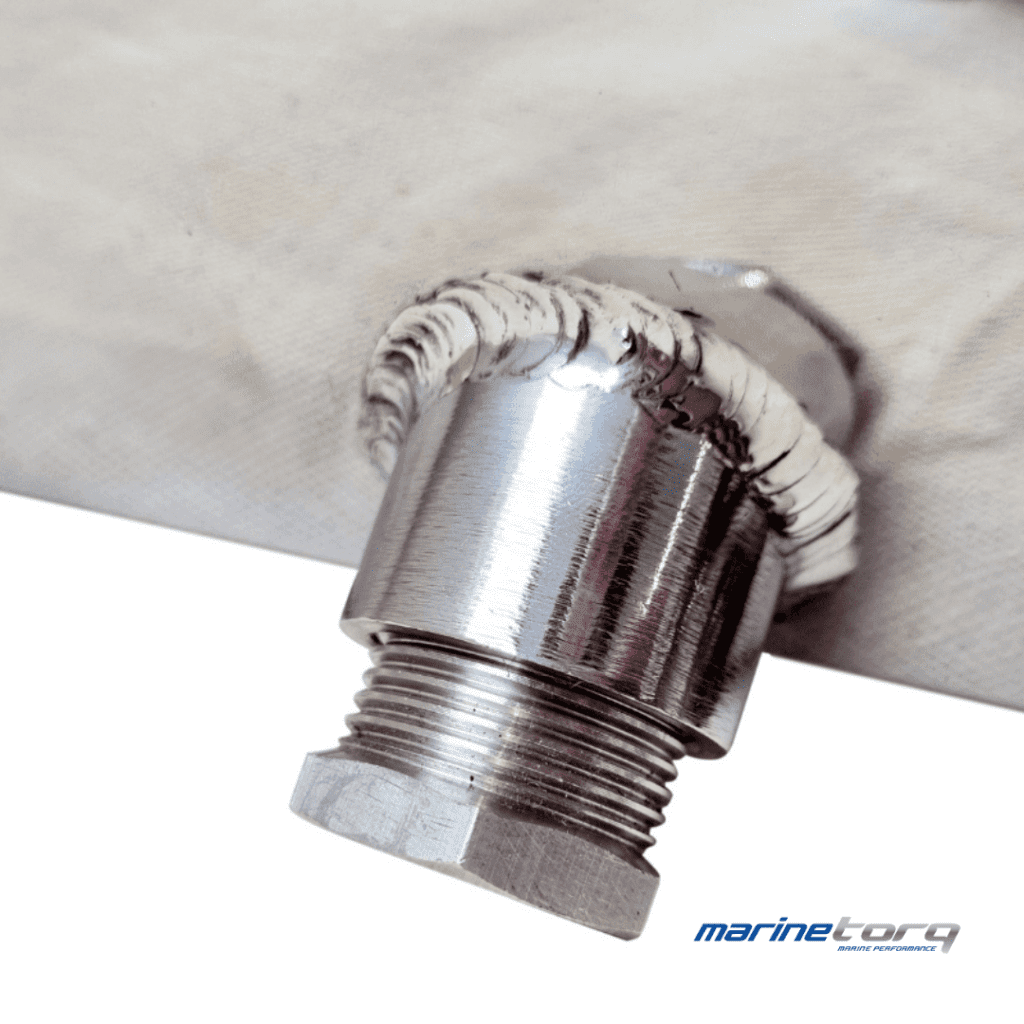

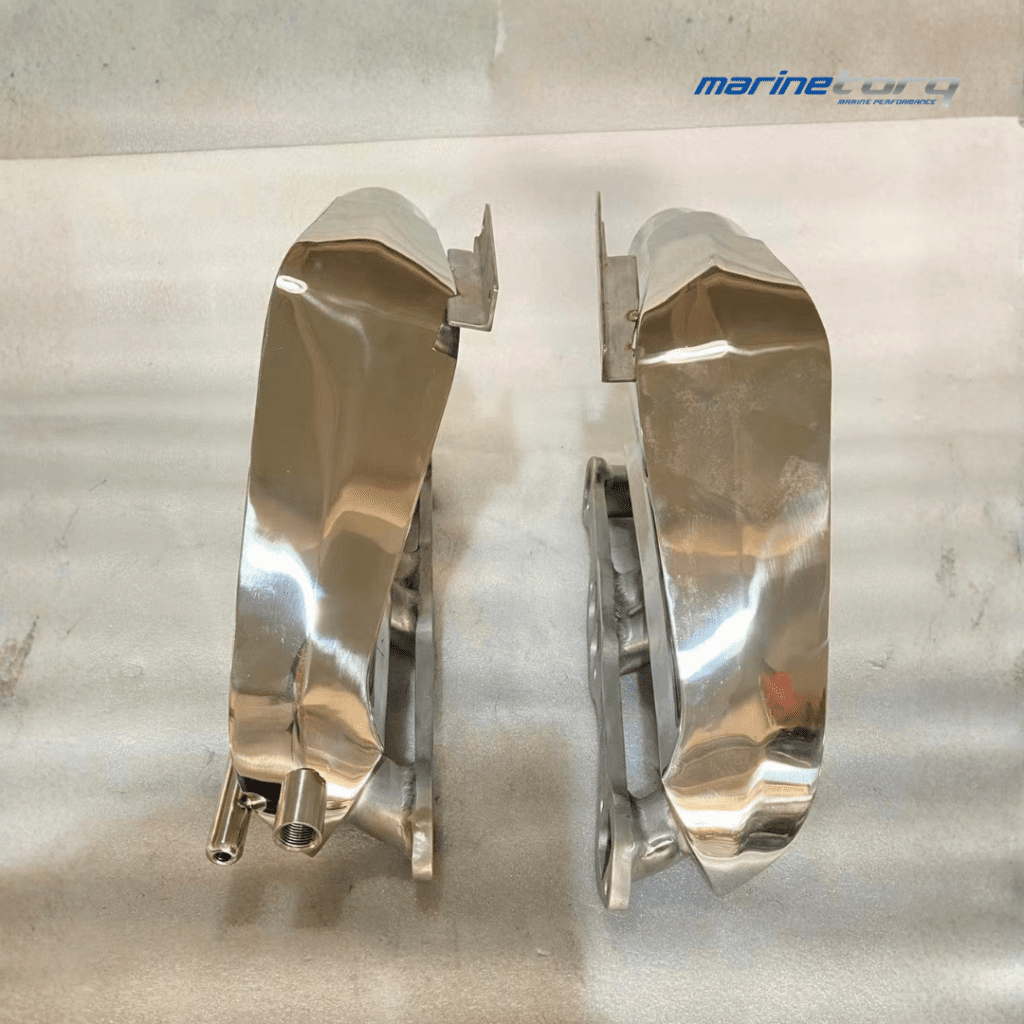

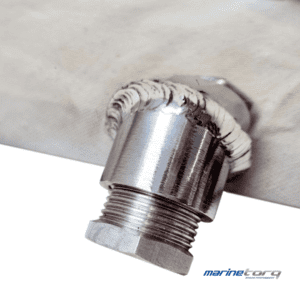

An in-built sacrificial zinc anode offers total protection against rust, preventing electrolysis and extending the manifold’s lifespan. As a highly active metal, zinc corrodes in place of the stainless steel and keeps the manifold in optimum condition. For why we use zinc, how often the anode needs replacing and more, click here.

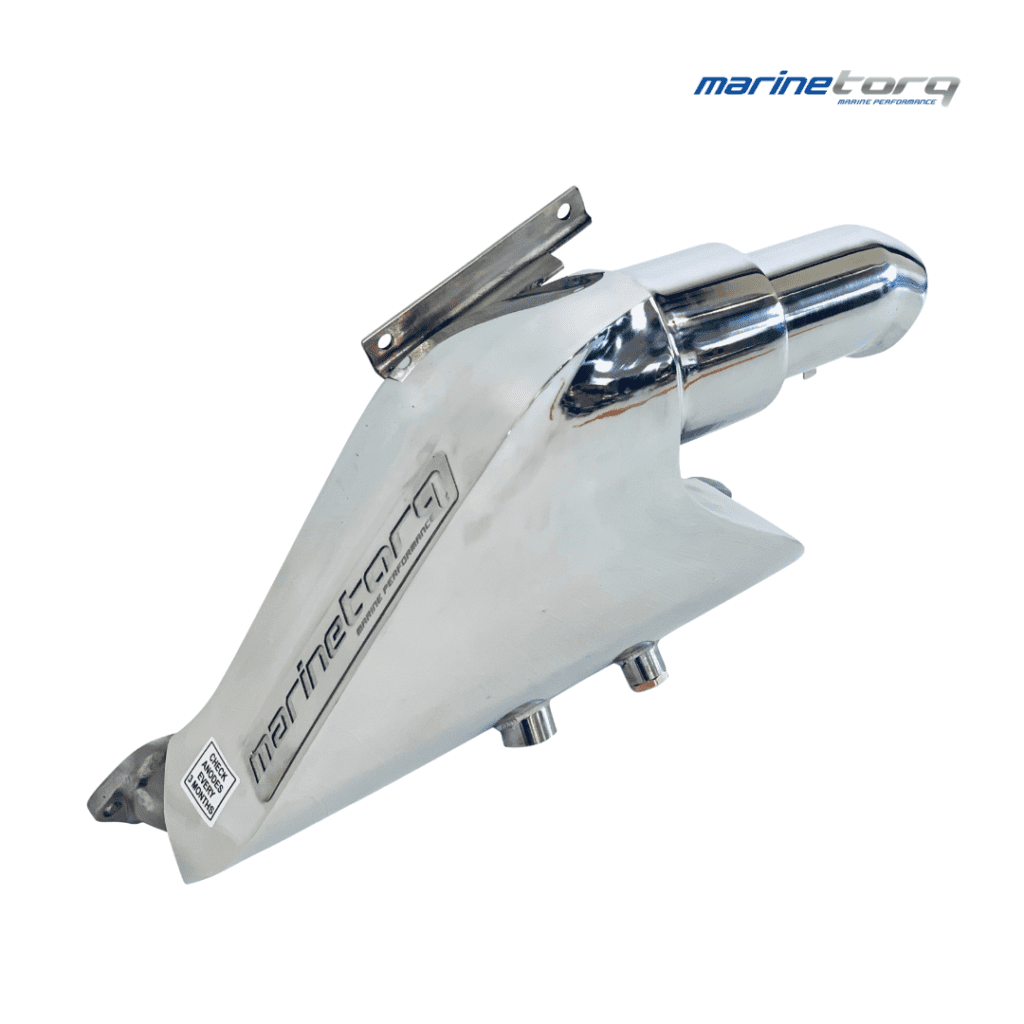

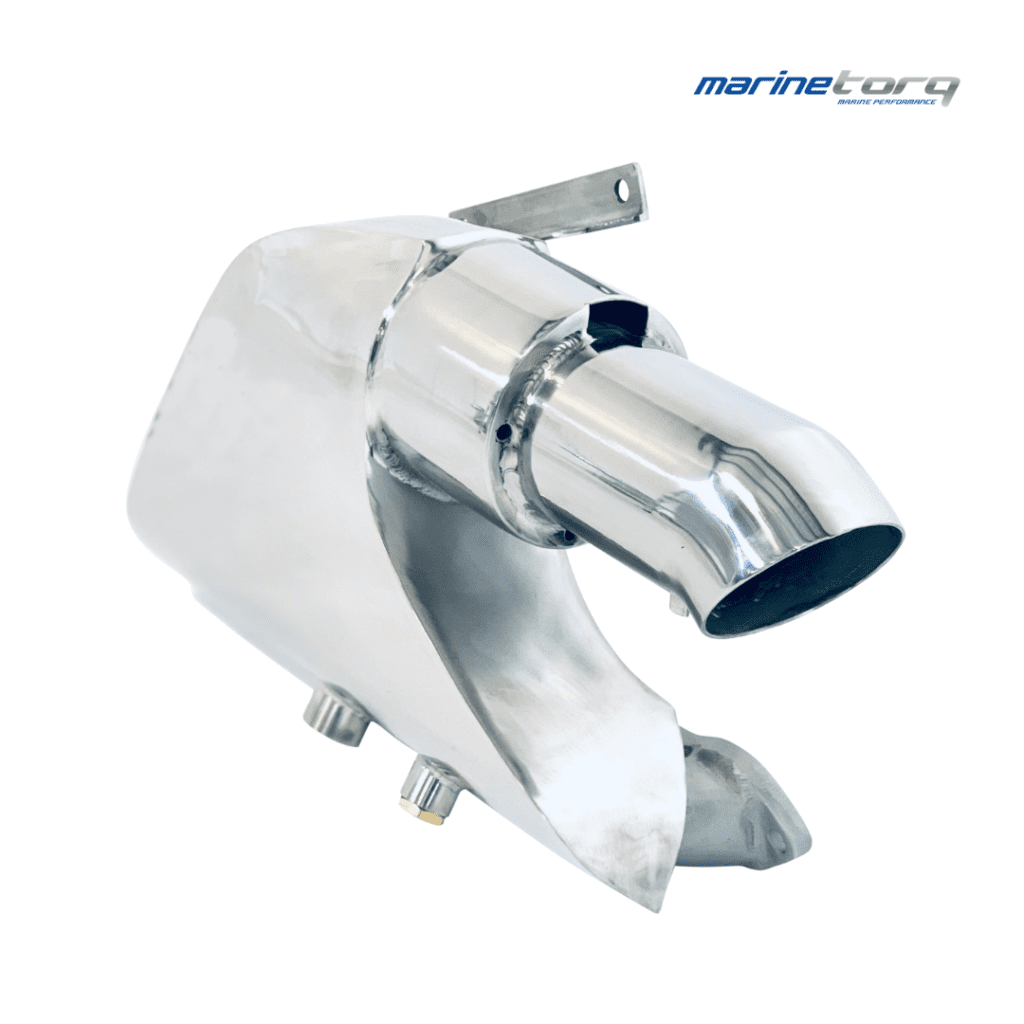

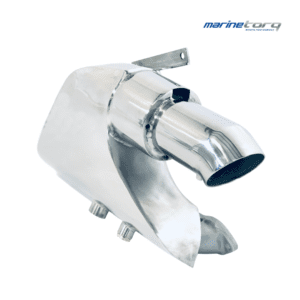

As an extra preventative measure, each MarineTorq manifold includes a unique anti-water reversion cone. This stabilises the exhaust flow as it exits the manifold, and prevents water from being sucked back into the engine. Learn more on the dangers of water reversion here.

The importance of timely manifold maintenance and replacement can not be overstated. With a MarineTorq Stainless Steel Manifold, you can reap the benefits of a much longer manifold lifespan and long-term savings. Plus, you can look forward to less time in the workshop, and more time out on the water enjoying a boat that runs smoother, faster, and more efficiently.

STAINLESS STEEL MANIFOLD FEATURES

One-piece Construction

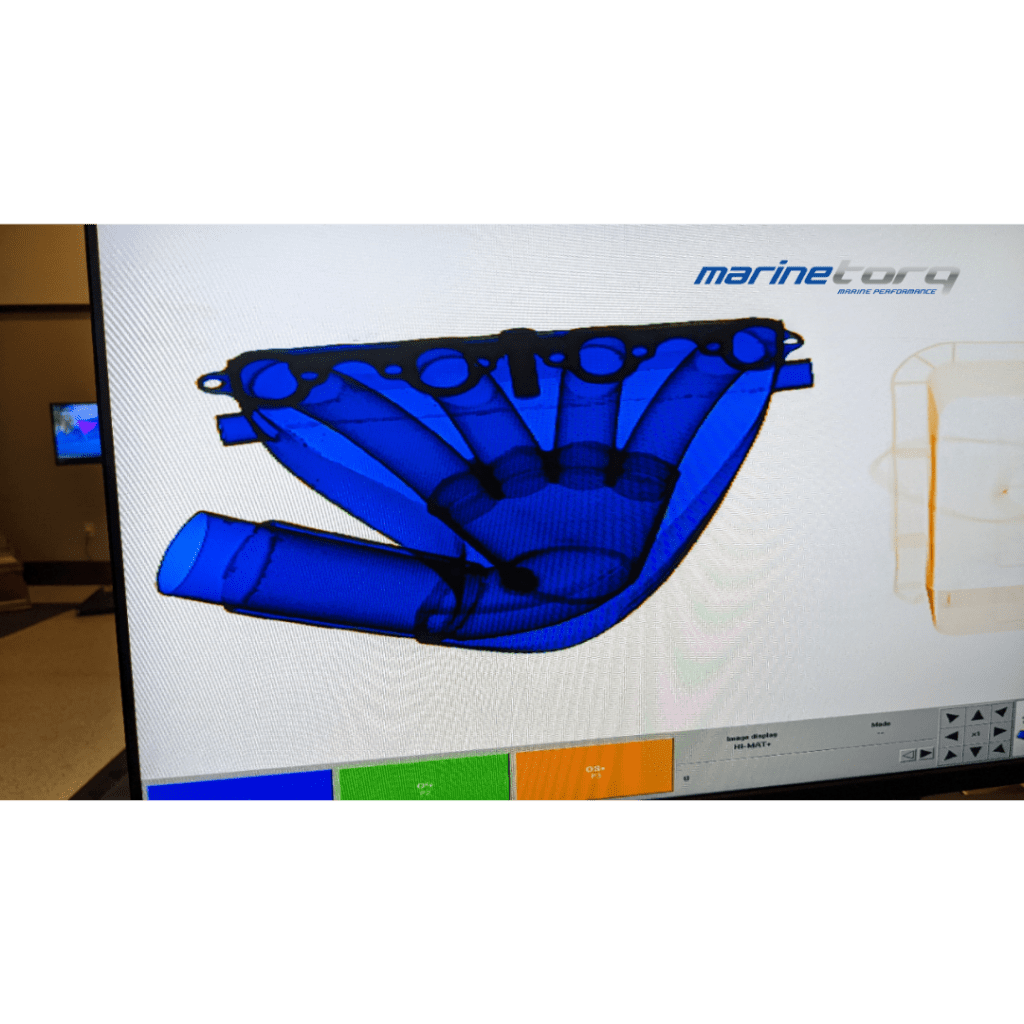

The patented one-piece construction of a MarineTorq manifold eliminates all joints and gaskets, which prevents rust, leaking and the likelihood of engine failure. A 2mm thick water jacket provides an additional layer of protection and increases the cooling process. Learn more on how MarineTorq’s manifolds are manufactured and tested here.

Thick Stainless Steel

MarineTorq manifolds are fabricated from 2mm thick premium stainless steel, which is a lightweight and rust-resistant alternative to cast iron. Reducing the dead weight of your boat for improved power, performance and efficiency, stainless steel also helps keep temperatures down in the engine bay. To watch a customer unbox a new set of stainless steel manifolds, and discuss why he chose stainless steel instead of traditional cast iron manifolds, check out this video.

Sacrificial Zinc Anode

All MarineTorq manifolds include a replaceable zinc anode to prevent corrosion. By adding another metal into the circuit, this anode ‘sacrifices’ itself by corroding, while keeping the manifold in optimum condition. We recommend replacing it every six months to maintain the product warranty and prevent corrosion. Find out more on how sacrificial anodes work and where to buy replacement anodes here.

Anti-water Reversion Cone

Keeping water and gases separated until they exit the riser is crucial to preventing rusting or worst-case scenario, hydro locking. MarineTorq’s anti-water reversion cone stabilises the exhaust flow as it exits the manifold, preventing water from being sucked back into the engine. Read more on the process of water reversion and how hydro locking occurs here.

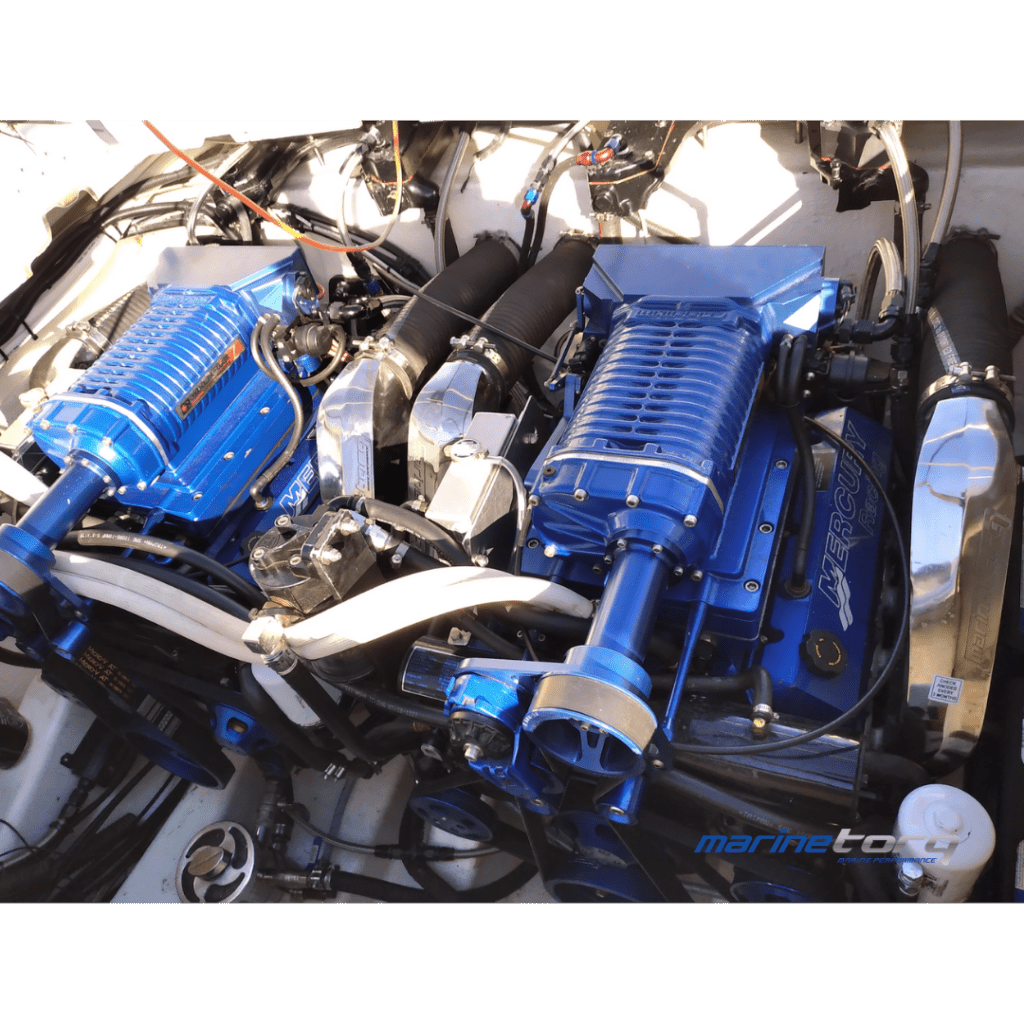

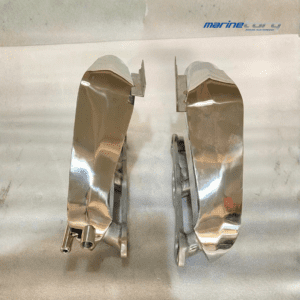

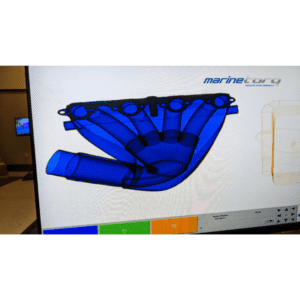

Custom Manifold Options

To accommodate different requirements, MarineTorq can customise risers, spacers, sensors and even the lean of manifolds before they are constructed. We can also alter the design to accommodate extra horsepower or a unique engine bay setup. Speak with a MarineTorq expert to get started on a custom manifold design for your boat today.

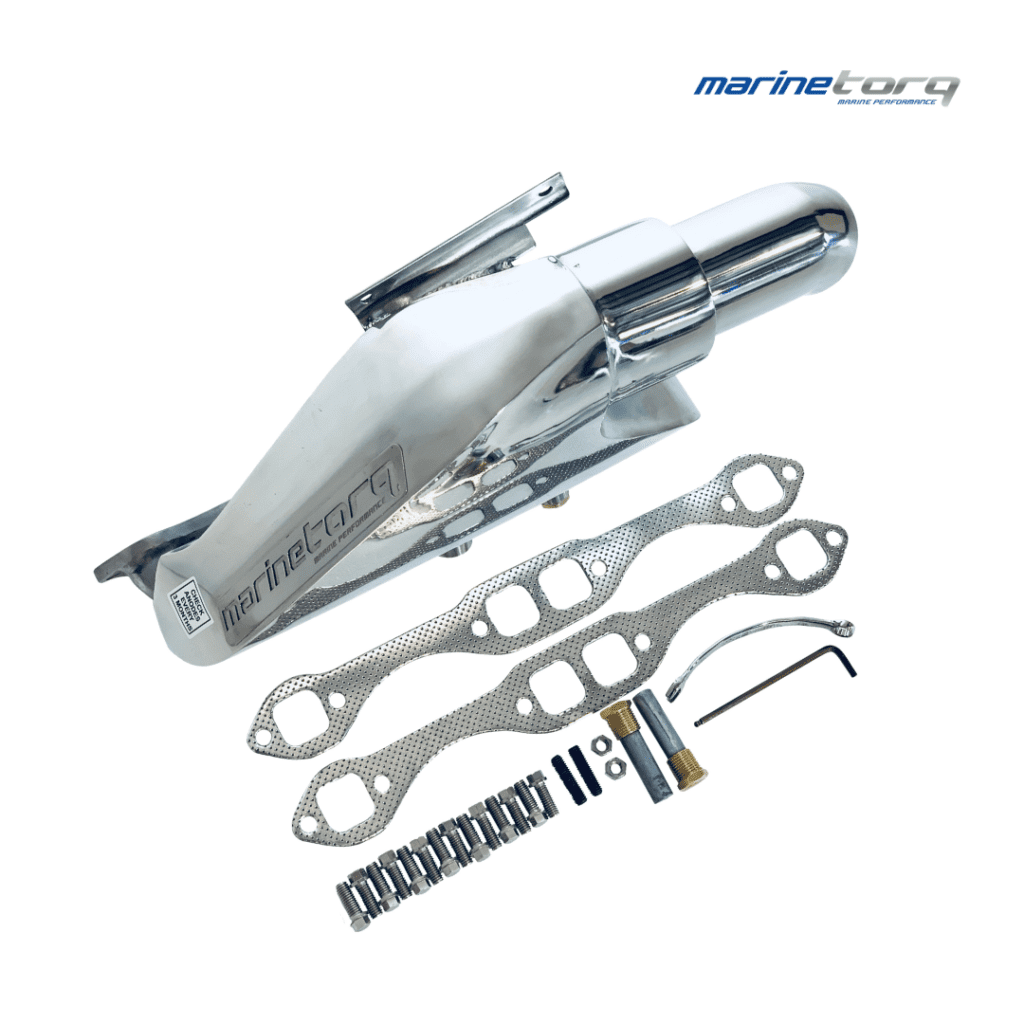

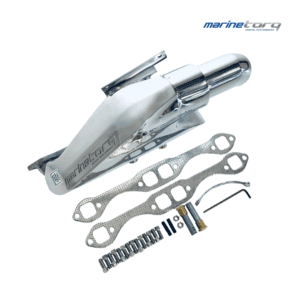

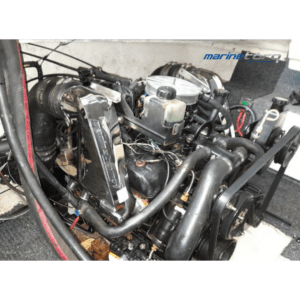

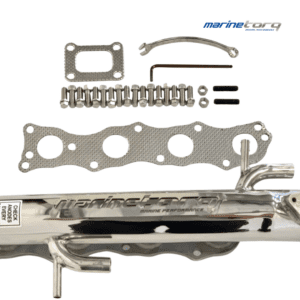

STAINLESS STEEL MANIFOLD INSTALLATION

Installing a MarineTorq stainless steel manifold is a one-man task. Each set has a full fitment kit, including a custom bent spanner for easy access in tight spots. Like a set of car extractors, the manifolds simply bolt on with 6-8 bolts from the flange into the engine heads.

Click on the instructions tab to watch a set of stainless steel manifolds be installed, plus receive tips on removing the original manifolds, cleaning, temperature and leak checks, and more.

FEATURES

- Seamless one-piece design

- Lightweight construction

- 2mm thick stainless steel

- Stainless steel water jacket

- Includes anti-water reversion cone

- Inbuilt sacrificial anode*

- Custom options available

- Simple bolt-on installation

- Full fitment kit included

- 5-year product warranty**

- Worldwide delivery

PLEASE NOTE

*Each manifold includes a sacrificial anode. We recommend visually checking the condition of this anode every three months and replacing it every six months to keep your warranty valid. For more information on our zinc anodes, click here. To order replacements or a Care Kit, click here.

**Our stainless steel manifolds come with a 5-year warranty, while stainless steel manifolds with catalytic converters are covered by a 2-year warranty.

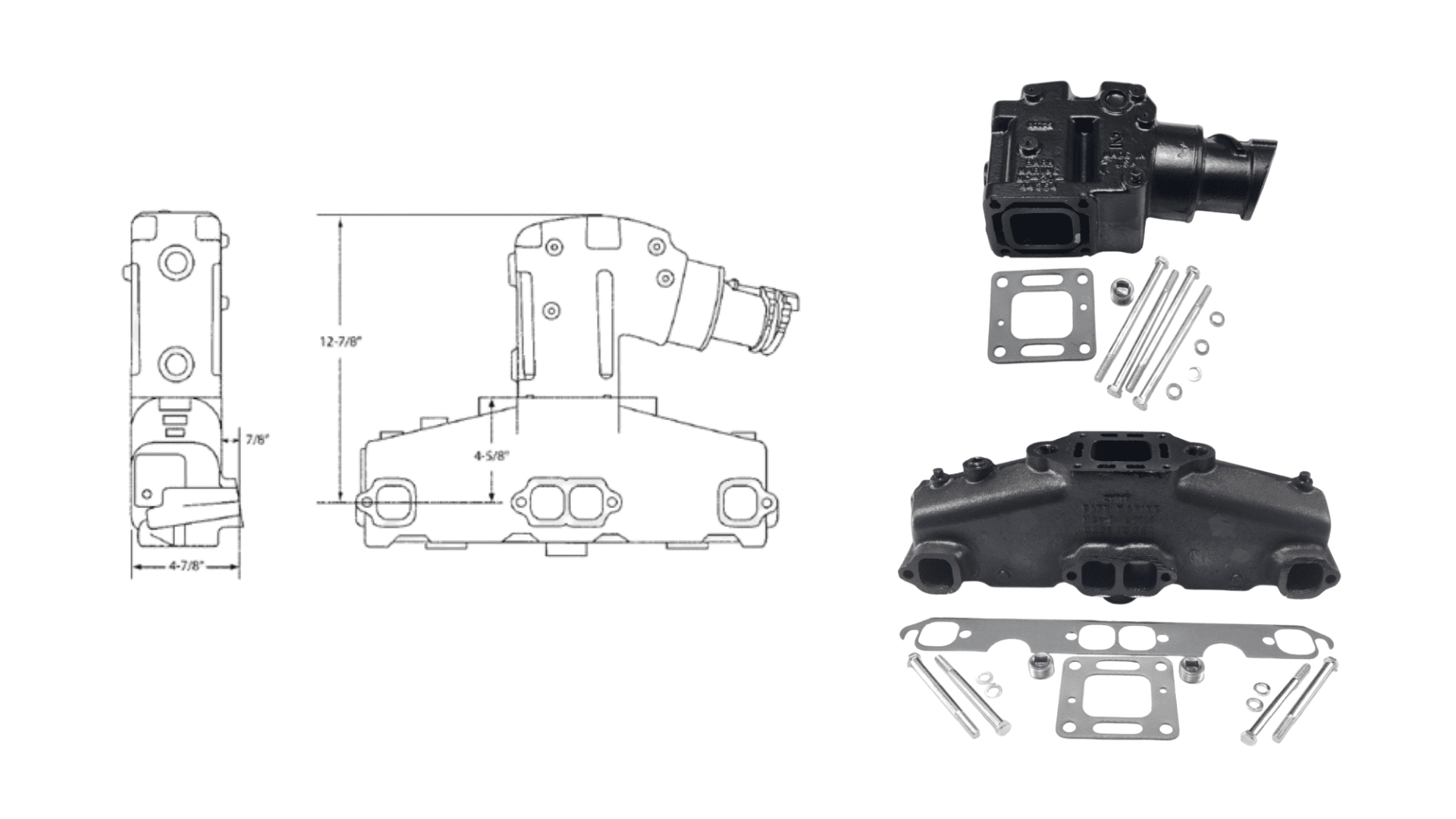

OEM Manifold This Replaces